AMB 2022

The machine: Multitasking

The company: Focus on the essentials

At AMB 2022, Bimatec Soraluce presents itself once again as a partner who does not simply deliver what the customer orders, but who listens carefully, analyzes the customer’s needs precisely and, in close cooperation with the customer, ultimately manufactures and delivers exactly what that customer really needs.

This customer proximity is also reflected in the development of the multitasking line that Bimatec Soraluce has launched. Because what is wanted are machine concepts that offer maximum flexibility in machining. The challenge is technically complex workpieces with tight tolerances that require various machining processes such as turning, milling, boring and threading. Bimatec Soraluce responded to this challenge and sets new standards with its multitasking machines: Milling, turning, grinding and gear cutting on one machine – in a single setup. This results in extreme machining accuracy and workpiece quality, enormously shortened set-up times, reduced floor space requirements, lower manpower needs and further cost benefits, as fewer tools, clamping devices and fixtures are required.

A key highlight of all Soraluce multitasking machines is the stepless indexing milling head in T-design with 37 kW drive power and a speed range up to 5,000 rpm. With the T-function, the milling head becomes a powerful “multitasking milling, turning and grinding head” with the same tool holder: Which means automatic tool change of the milling and turning tools via a standard tool changer. In addition, the main spindle is clamped during turning for zero backlash and increased stability.

The developed multitask concept “All in one” is available for bed type milling, turning and grinding machines (T range), floor type milling and turning machines (F range), portal milling and turning machines (P range) and vertical turning centers (VTC range) or customized large machines, so that pendulum machining, multi-station machining and automatic palletizing are possible for any workpiece size.

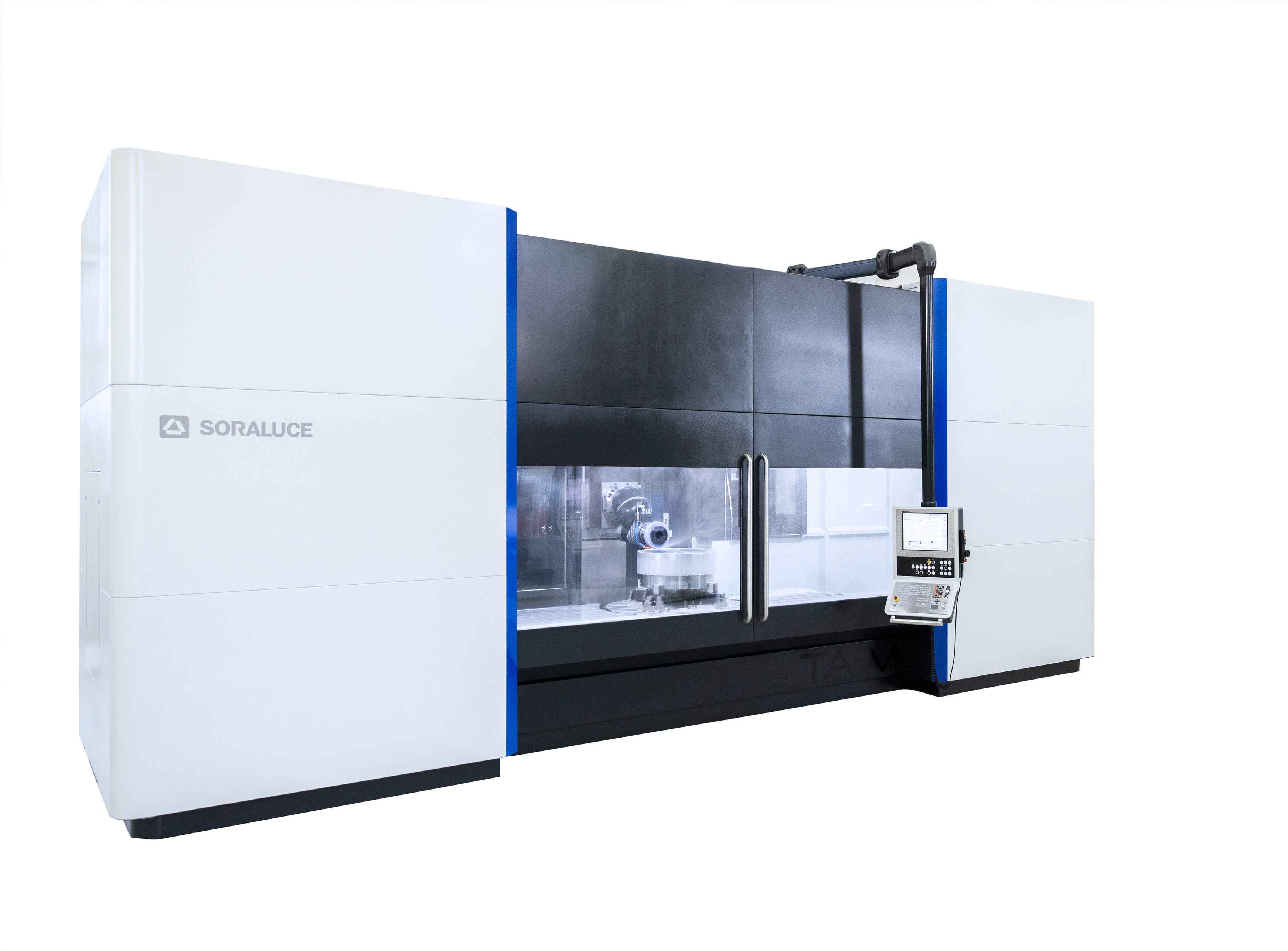

Live at the AMB: The SORALUCE Bed type milling, turning and grinding machine TA-M 35

At the AMB, Bimatec Soraluce presents this technological progress through a customer machine, the SORALUCE Bed type milling, turning and grinding machine TA-M 35. It was purchased by Feinwerk GmbH, a contract manufacturing company from Baden-Württemberg, where the machine will go into operation after the AMB.

“We were looking for a machine with the broadest manufacturing profile possible. Being a contract manufacturer, you are simply more flexible with it. Multiple machining capabilities on one machine – that’s generally an option that not many machines provide. This also allows us to offer additional services.”

Dominik Obert Management of Feinwerk GmbH

Feinwerk has not selected the grinding option for the time being, but it can easily be added later.

The customer’s machine is not equipped with a classic positioning table, but with a fast-turning table. So the hardware for grinding is already included, the only thing missing is the cycle package for the grinding function, which can be integrated subsequently on the software side without much effort.

Trade show visitors can expect a machine with:

- Longitudinal travel (X): 3,500 mm | Vertical travel (Z): 1,500 mm | Cross travel (Y): 1,200 mm

- HEIDENHAIN control system TNC 640

- Automatic indexing milling head with spindle clamp for rotary function, stepless indexing, 5,000 rpm

- Automatic tool changer with 40 magazine pockets

- DAS+ (patented) for machining without chatter

- Automatic feed control / Soraluce Adaptive Control

- Two swarf conveyors / Chipbreaker

- Complete splash guard enclosure

- Compact design for installation without separate foundation

- Maximum 8,000 kg table load for milling, 2,000 kg for turning and grinding

- Integrated NC rotary table Ø 1,250 mm

- Universal milling head for machining at any angle

“You have the rotary table, you can turn the head correspondingly, so you can reach well from all sides, allowing you to mill in a proper position as well. That’s really good.”

Dominik Obert Management of Feinwerk GmbH

Further technology developments from Bimatec Soraluce for process optimization

One of the biggest challenges in machining is vibration of the machine and/or the workpiece. Soraluce can identify the origin of the chatter and, in collaboration with its technology center, has developed various solutions to reliably eliminate vibrations and oscillations in the machining process, thus increasing productivity:

DAS+ overseas the machining process and detects any vibrations in the machine. It automatically selects the best technological alternative to eliminate chatter such as active damping in the ram, optimization of the spindle speed or oscillation of the spindle during machining.

The portable and patented damping system “Dynamic Workpiece Stabilizer” (DWS) is used to eliminate vibrations during the machining of unstable workpieces. It consists of a controller and one or more inertial actuators that can be easily attached even to thin-walled workpieces such as welded structures – either magnetically or using vacuum technology. DWS guarantees 5 to 10 times the cutting performance through chatter-free machining as well as improved surface finishing. Costly special tools or customized solutions for clamping the workpieces are thus history.

You can convince yourself of the efficiency of the intelligent damping solutions DWS and DAS+ to counteract vibrations in the machine or in the workpiece live at the AMB. Do not miss it – the effect is audible and visible to the naked eye.

The Bimatec Soraluce automation solutions

Soraluce is able to tackle automation projects at all different levels. From a single machine with a simple pallet transfer control integrated in the CNC to a flexible machining cell composed of multiple machines with workpieces up to 7 x 2 m and tool feeding systems managed by an Industrial PC to support very complex management software.

Soraluce has developed a customised Control System software to manage the machining cell using the job list concept. All the elements that make up the cell: machines, workpieces, pallets, tools, CNC programs, etc. are integrated by means of this software, making the operation easy.

Customers and Bimatec Soraluce – a partnership of equals for over 30 years

Bimatec Soraluce has been operating on the market for over 30 years and continues to place the customer and the machine operator at the center of all technological developments. The objective here is the intelligent machine that boasts higher accuracies, improved efficiency, ease of use, ergonomics and safety while reducing cycle times, downtime and consumption of emissions. Because that gives the customer the decisive competitive advantage that matters. At the end of 2017, Bimatec Soraluce set a goal in its vision by 2020, not only to manufacture high-tech machines, but also to offer a first-class and unique service with more transparency, quality and speed in all service processes. In 2019, the restructuring has already been almost fully completed successfully. With 21 new service, training and technology specialists, the service and support division for customer care was expanded by 50 % and a new training center was opened in January 2020. A new training portal on the website allows customers to put together their own ideal training and development program.

“Our ambition is to provide our customers with customized products with the best technological solution for their production. The great innovativeness of the Danobatgroup offers us the best prerequisites to work close to customers in our markets, to know their requirements and to meet them with our products.”

Oliver Krause, General sales management Bimatec Soraluce

Service around the clock

The unique service concept includes a service hotline with eight employees who are available on weekdays in a shift system and on all weekends and holidays throughout the year. The regional service fleet with eight service buses is unparalleled in the field of large-scale machining centers to date. The service fleet is to be expanded to 13 service buses. With the regionally based service technicians and the very well equipped service buses, 60 % of the troubleshooting is now already carried out on the same day, and thus the company offers competent immediate assistance 365 days a year.

In addition, Bimatec Soraluce has 67 replacement and loan milling heads available and supplies customers with the loan milling heads and high-quality original spare parts within 24 hours. The uniqueness is that each rental milling head is completely checked and overhauled after it has been in operation at the customer. This means that “every” customer receives a rental milling head with exactly the same quality as his original milling head and does not have to accept any cutbacks. Bimatec Soraluce’s experienced technology specialists support, analyze and evaluate customers’ production and machining processes on request and develop the optimal machining solutions for each specific application. Always with a focus on increased precision, optimized machining processes, increased machine capacity and reduced cycle times. Customers can also rely on the experience and expertise of Bimatec Soraluce for upgrades, retrofits, and modernization of older Soraluce machines.

“We too are keeping a close eye on current events and their impact on energy and raw material prices, supply chains and Germany as a business location. Shortages of gas and expensive electricity are currently having a lasting negative effect on our customers’ willingness to invest.

Nevertheless, we are cautiously optimistic about the current fiscal year and a strong 4th quarter 2022. The opportunities outweigh the risks and the trend of deglobalization is getting to local producers. Since before Corona, we have taken a regional supplier approach with our corporate group, which has proven to be very resilient over the past two years. Of course, we also have additional expenses in material procurement and production planning, but we can still deliver on time and remain a reliable partner for our customers.”

Thilo Borbonus, Managing Director / Shareholder Bimatec Soraluce