Milling heads

“…BECAUSE IT’S THE HEAD THAT COUNTS!”

Our milling heads have been the heart of our machines since 1988! A milling head concept unrivaled to date is the cornerstone for maximum flexibility, precision, and availability. Today, our customers benefit from our 30 years of experience in the design and manufacture of our milling heads. The design, the complete production, assembly and quality control of the milling heads is carried out at our own facilities and are the basis for the success of the Soraluce milling, turning, and boring centers.

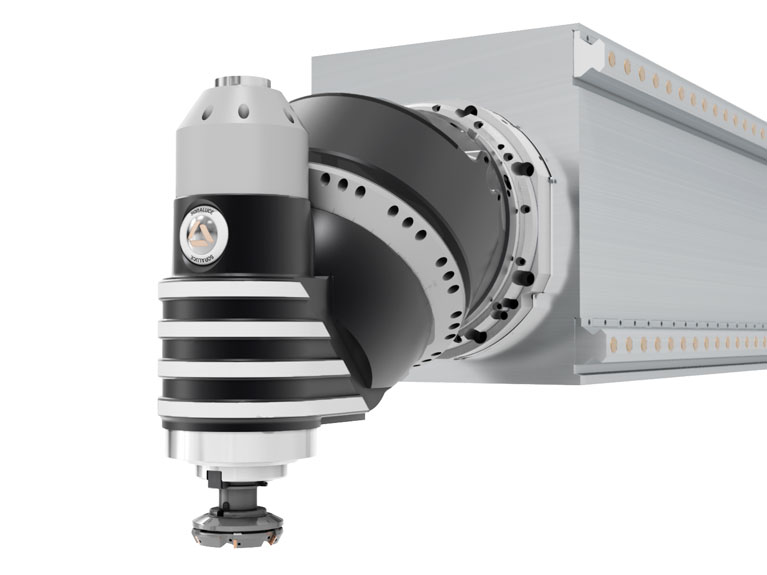

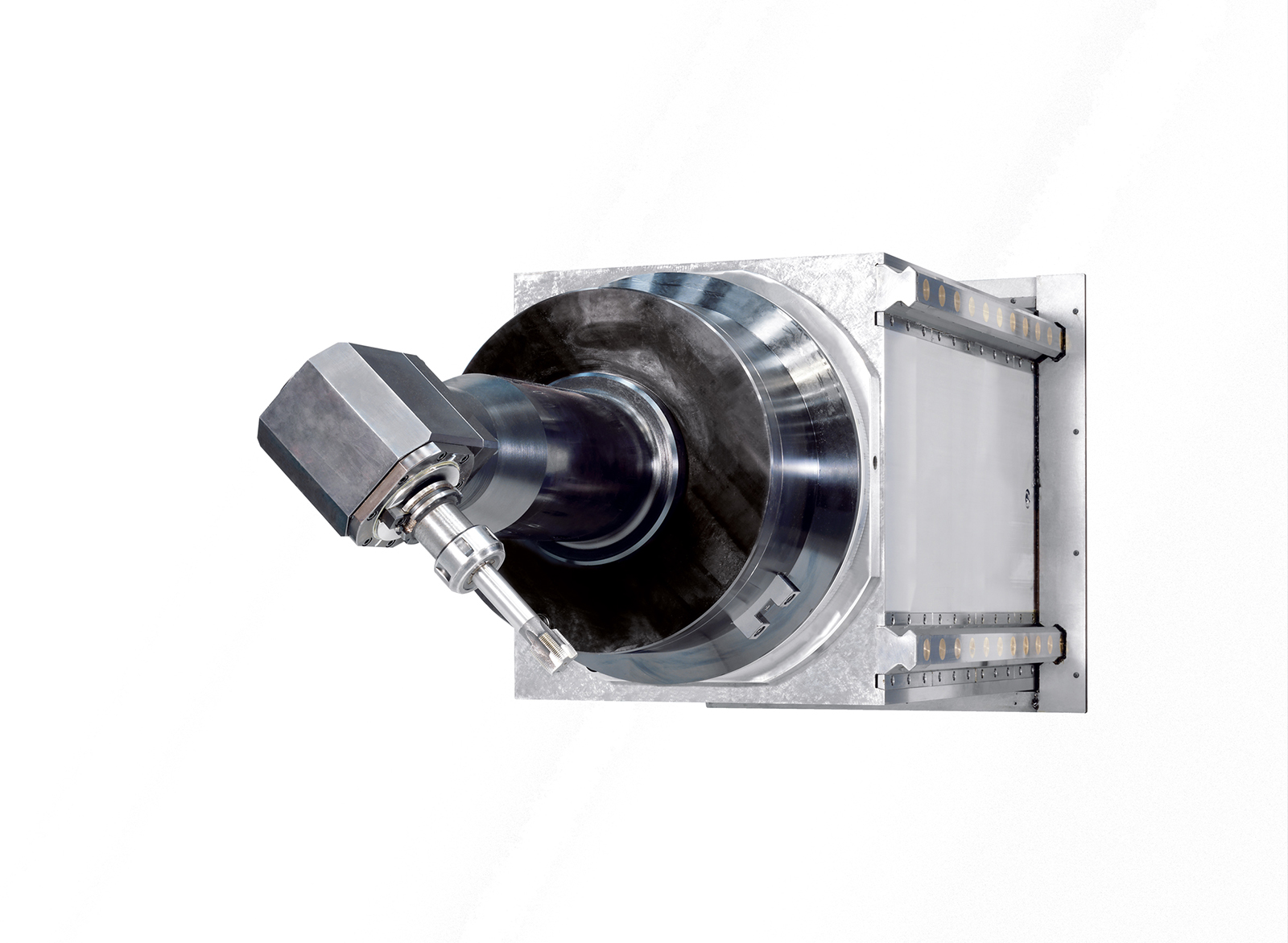

Universal milling head

| Drive capacity |

37 / 60 kW |

| Pitch | 2.5° x 2.5° / 1° x 1° / 0.001° x 0.001° / simultaneously infinitely variable |

| Speed range | 4,000 / 5,000 / 6,000 / 7,000 min⁻¹ |

| Tool holder | SK 50 / HSK 100 |

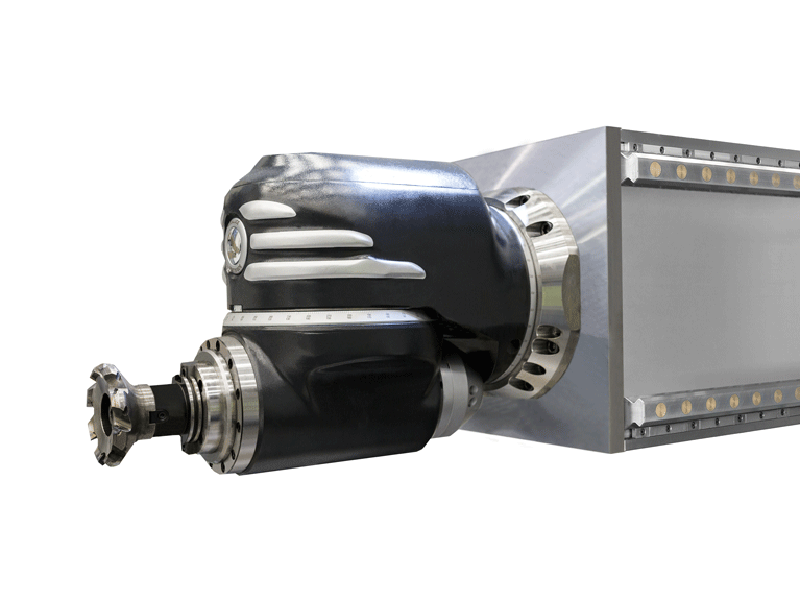

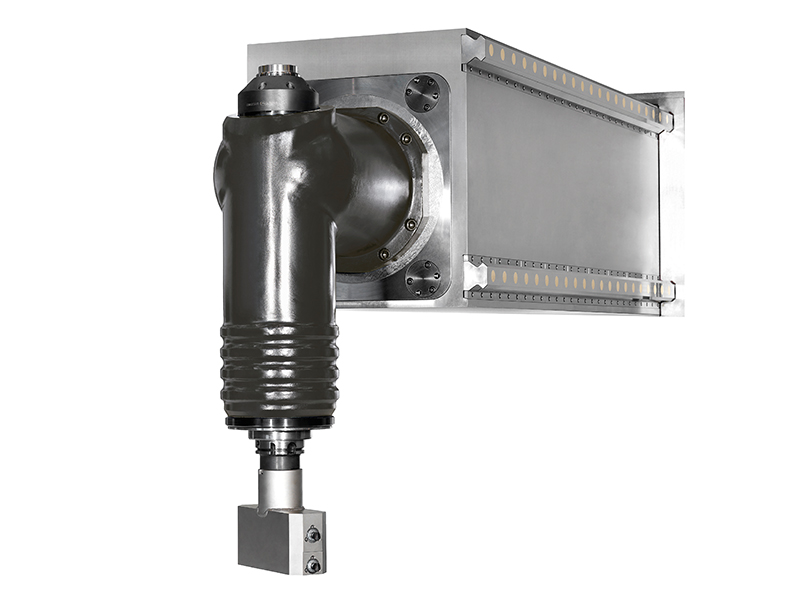

Orthogonal milling head

| Drive capacity | 37 / 46 kW |

| Pitch | 1° x 1° / 0.001° x 0.001° |

| Speed range | 4,000 / 6,000 min⁻¹ |

| Tool holder | SK 50 / HSK 100 |

Orthogonal 2-axis NC milling head

| Drive capacity | 25 / 74 kW |

| Pitch | 25 kW simultaneous swiveling |

| Speed range | 12,000 / 18,000 / 24,000 min⁻¹ |

| Tool holder | HSK 100 / HSK 63 |

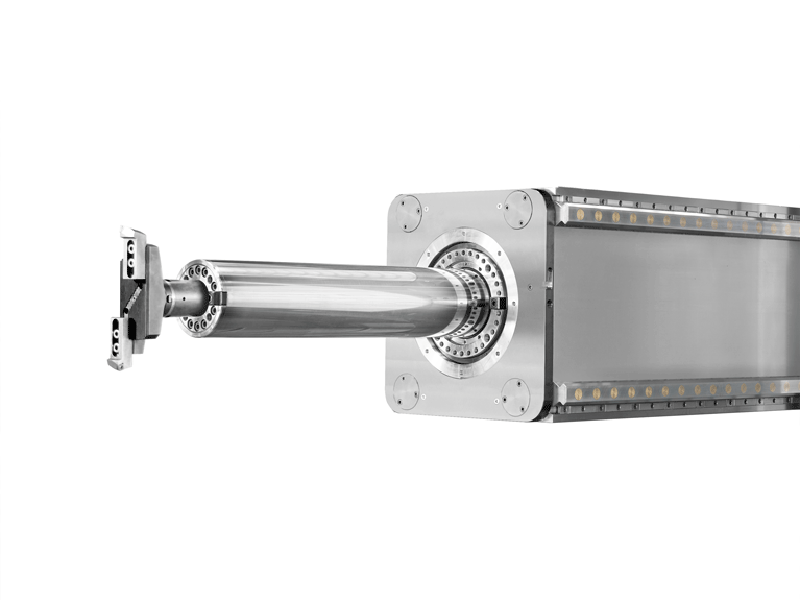

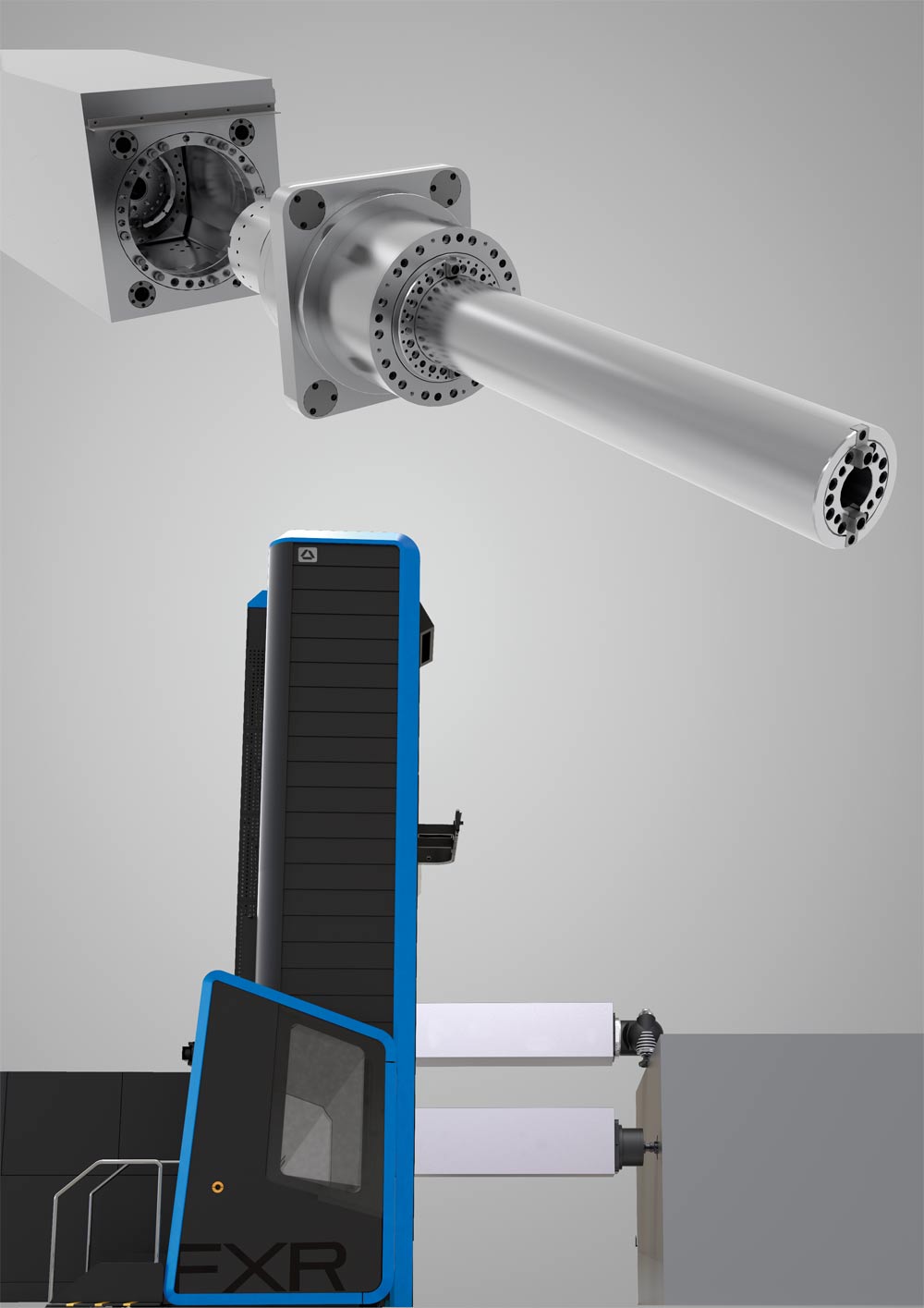

Quills

| Drive capacity | Up to 101 kW |

| Diameters | 130 / 150 / 180 mm |

| Speed | Up to 3,000 min⁻¹ |

| Torque | 2,030 to 10,907 Nm |

Face drilling head

| D`Andrea face and drilling heads for ∅ up to 1,600 mm |

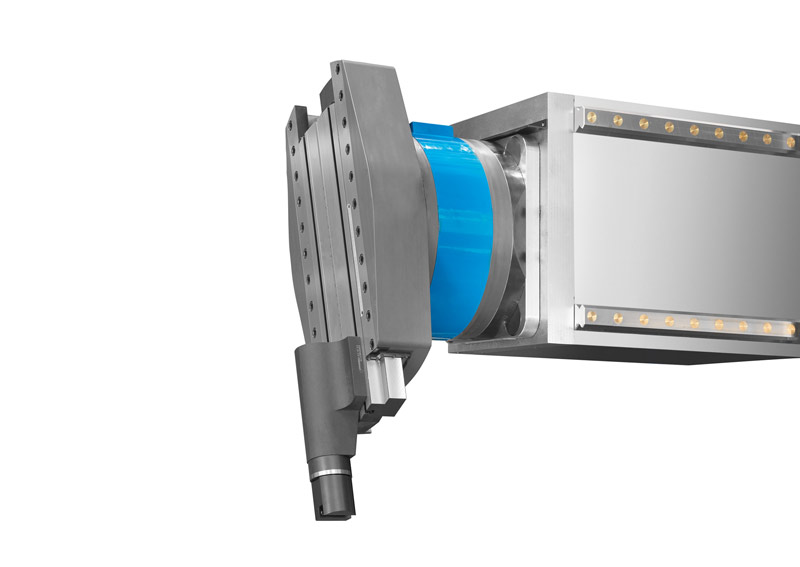

Angular milling head

| 90° angular milling heads with C-axis | 2.5°, 1° or infinitely variable swivelable. |

| Length according to customer requirements | |

| Tool holder ISO 50 |

Long angular milling head

| 90° angular milling heads with extended spindle for plunging into deep workpieces such as motor blocks | Length according to customer requirements |

| Tool holder ISO 50 |

Miles ahead through top manufacturing quality

Soraluce milling heads are manufactured and assembled in air-conditioned and dust-free rooms to ensure exceptionally high manufacturing quality. The milling head technicians have at their disposal the most modern production machines such as Yasda and Dixi jig boring machines with an accuracy of less than 0,005 mm and special assembly systems. The quality of the milling head components is controlled by Zeiss measuring machines and the function control on modern test benches and test machines. Up to 240 milling heads are produced per year and used on Soraluce machines.

Our milling heads form a structural unit with the ram. One third of the milling head is guided inside the ram. The small distance between spindle and ram results in lower lever forces and higher stability. Our milling heads are stepless and positioned by a main spindle motor and rotary encoders integrated in the ram. The advantage: No electrical components in the milling heads and fewer sources of malfunction.

At a glance

- Innovative technology

- 30 years of experience

- Our own manufacturing and production

- 50 standard milling heads

- Replaceable within two hours

- Loan milling heads on site within 24 hours

- 64 loan milling heads from our Limburg site

Always the same!

It all depends on the connection!

Every customer has his own challenges and needs solutions to survive in the market. In order to provide our customers with optimum support, we offer a very wide range of more than 50 standard milling head models and special solutions on request. We thus deliver the ideal solution for virtually all applications. The connection to the ram is the same for all milling head models. This means that all milling heads can be replaced within only two hours – a unique service for our customers. Replacement milling heads are also available for our customers – with 24-hour delivery! Our milling head concept demonstrably stands for minimum downtime and maximum productivity. To the benefit of our customers.

Automatic quill / milling head changing system for maximum flexibility

Since 1996, we have been offering our customers a milling head changing system for several milling heads for complete machining of workpieces. It consists of adapter plates with a sophisticated plug & play system. This means that all standard milling heads and loan milling heads can be used by one milling head changing system. High-precision positioning is achieved by the Hirth coupling on the adapter plate and in the ram and clamping by four zero-point clamps. All media are transferred by quick-release couplings. Manual intervention is not necessary.

We have also been offering our customers a milling head / quill changing system since 2014. This worldwide-patented system is unique: For the first time it is possible to use machines with a variety of quills. Depending on requirements, a quill with a diameter of 180 mm or 130 mm can be changed fully automatically – within 90 seconds! The same applies to an automatic swiveling milling head, without loss of cross travel, as is the case with conventional jig-drilling machines. The Soraluce milling head / quill changing system has been successfully used by customers for four years.

Do you have any questions?

Get in touch with us