Manufacturing technology

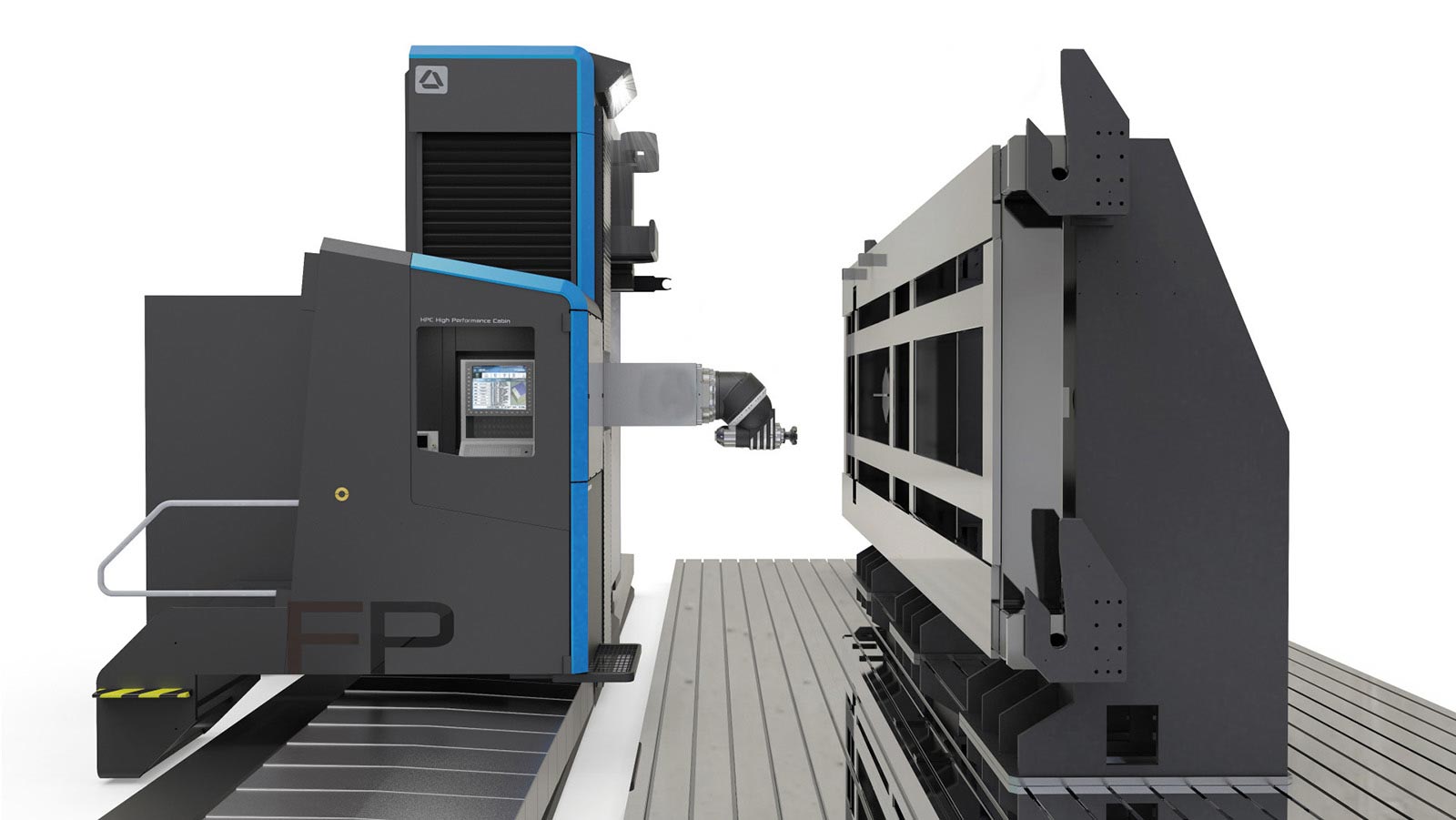

We are dedicated machine manufacturers and engineers. Bimatec Soraluce develops, manufactures, services, and sells intelligent, flexible milling, boring and turning centers as well as vertical turning and milling centers. We have been constantly developing our products and technologies since the company was founded in 1991.

Our research and development center is doing pioneering work in many areas such as the use of INA linear guiding systems with hydromechanical damping slides and the standardization of connections between milling heads and ram slides with only four standardized connection versions. The advantage: Our milling heads can be replaced with loan milling heads within only one hour.

German engineering at its finest

Our engineers and technicians continuously analyze the requirements of the market in order to develop and establish new technologies and products. They are your direct point of contact for applications, cutting time calculations, machine configurations, and feasibility studies. As an interface to technology carriers, they are in constant contact with tool manufacturers, equipment manufacturers, and control system producers. They carry out test machining in our technology center, in our production plant, and at our customers’ sites. They support project management in the implementation of technologies and advise customers on machining technologies, tool selection, and software adaptations – throughout the life of the machine. Because we understand all this as German Engineering.

Technology and know-how – that’s our technical edge!

Feasibility and time and motion studies

Our technology department is always very particular when it comes to machining tests, for example. The customer’s production technology used to date is put to the test, the results are analyzed, and customer is given advice right from the very beginning.

In addition, our technology specialists prepare time and motion studies to thus secure investments and profitability. How do our customers benefit: Our new tool technologies, programming settings, and milling strategies have demonstrably reduced machining times by up to 70%.

On request, our experienced specialists from the technology department will also provide customers with sound production planning services by creating machining plans, collision analyzes, time studies, and clamping concepts. The result is efficiently planned machining processes, more planning reliability, and better competitive opportunities.