Take your manufacturing process to the next level with the New Dynamic Line High Rail Gantry Machines of Soraluce! High speed cutting, great precision rates and high-volume machining capability, backed by our extensive experience in the milling sector and proven state-of-the-art technology.

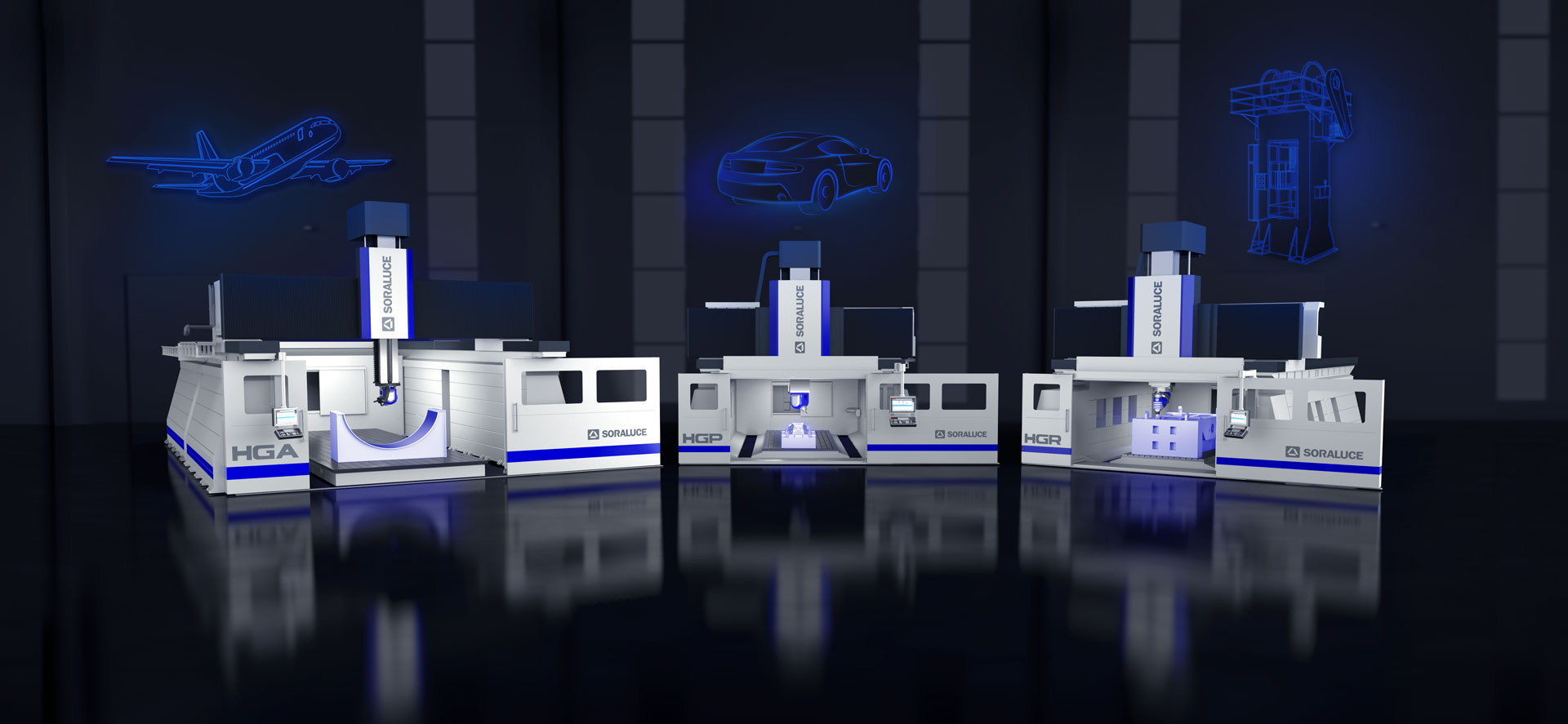

Three machine models oriented to applications in different sectors like the aerospace, mold & die or mechanical engineering, including solutions to machine specific materials like composites, light alloys or steel-based components.

High Dynamics

Experience groundbreaking efficiency with high-speed cutting.

Axes speed up to 60,000 mm/min.

Axes acceleration up to 4 m/s2.

5 axis contouring heads up to 30,000 rpm.

Precision Excellence

The finest surface quality for your finest work.

Best rigidity and stability.

No chatter during the machining process.

Thermal stability.

Cutting Power

Unmatched cutting capacity for optimal performance.

Heavy-duty mechanical heads up to 73 kW.

Variety of high torque mechanical 5 axis contouring heads up to 2,000 Nm.

Smart Damping Solutions (DAS+, DWS).

Full cast iron structure.

Discover Dynamic Line Range

New HGA

- Machining of composites and aluminum.

- High-volume machining capability.

- 5-axis contouring fork type milling heads.

- Complete splash guarding.

- Dust extraction system on the head.

New HGP

- Semi-finishing and finishing in steel and aluminum.

- Mold & die machining.

- 5-axis contouring fork type milling heads.

- Complete splash guarding.

New HGR

- Machining of stainless-steel parts.

- Highly versatile.

- High stock removal rate.

- Automatic head changing system.

Contact us

If you would like to receive information on our products, services or solutions, or for one of our colloborators to get in touch with you, fill in the following form.