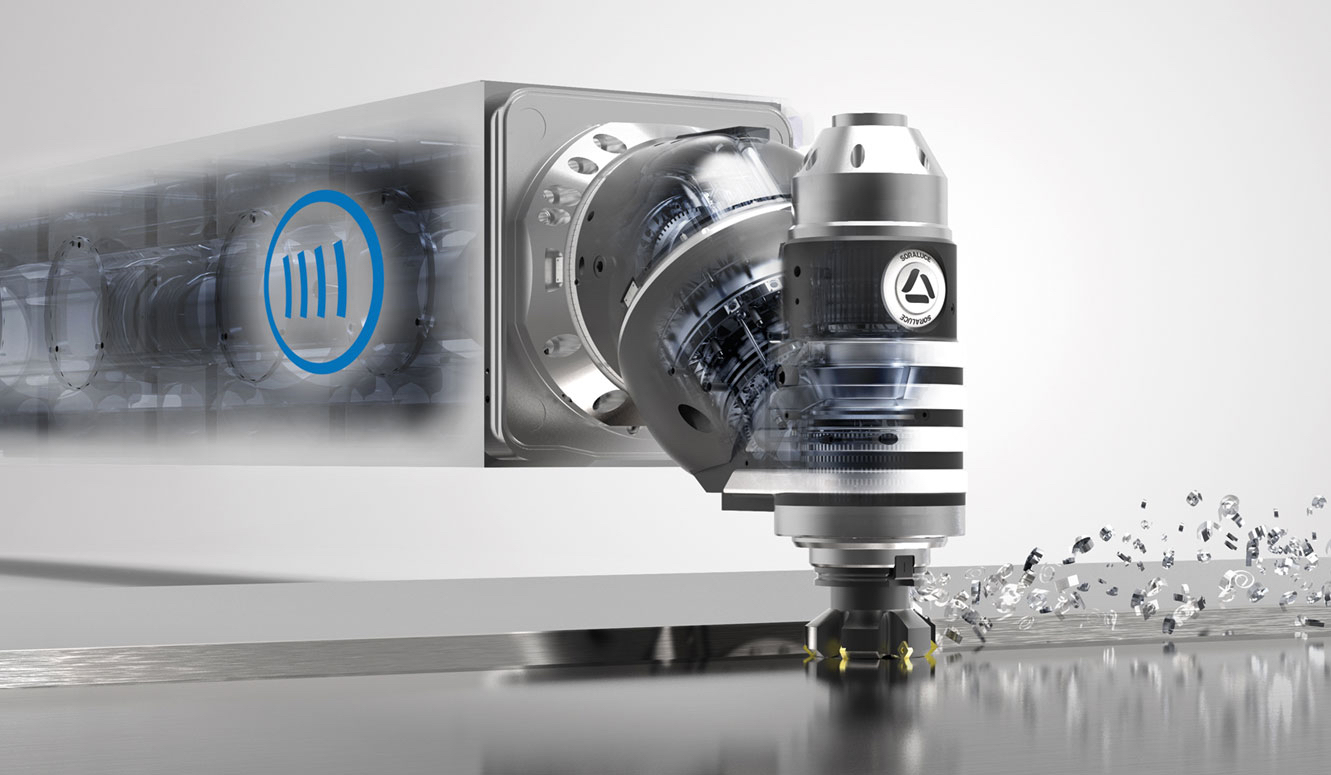

No more chatter!

DAS+®

DYNAMICS ACTIVE STABILIZER

With its additional functions, DAS+® eliminates chatter and the associated vibration that traditionally occurs during milling, turning, and boring operations. The result is a smooth, optimal, and fully automatic machining process!

Advantages for the machining process

- Full utilization of the machine capacity

- Up to 300% higher cutting performance

- 45% shorter production time

- 25% less tool wear

Advantages during machining and maintenance

- Simple handling and operating

- The function can be switched off and on at any time, in any operation mode and even during machining

- Less machine wear

Background

Vibrations during milling, turning, and boring create an irregular machining process and result in quality losses on workpiece surfaces, reduced tool life, and increased machine tool wear.

Solution

The patented DAS+® system is one of the most innovative technologies in the field of milling, turning, and boring in the machine tool industry. DAS+® automatically controls and monitors the manufacturing process with sensors and detects any vibrations occuring right from the start. Specially developed actuators generate counter-frequencies to eliminate vibrations in real time. The SSV function additionally adapts the spindle speed.

The result is impressive: A smooth, optimal, and fully automated machining process with the same processing conditions throughout the entire work area and independent of the machine concept. We guarantee maximum cutting performance even with a fully extended RAM.

DAS+® automatically controls and monitors the manufacturing process with sensors and detects any vibrations occuring right from the start.

Jan Lauer, Sales Manager

Do you have any questions?

Get in touch with us.