Always high precision!

DBS

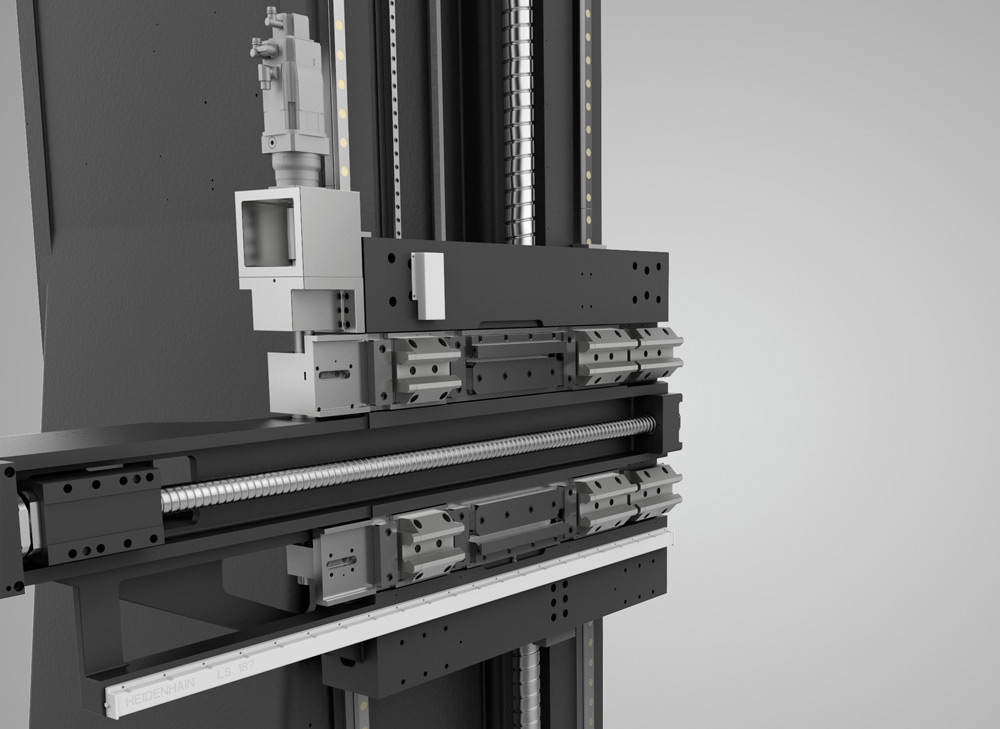

DYNAMIC RAM BALANCE COMPENSATION

DBS guarantees maximum precision in straightness, parallelism, and flatness over the entire travel range of the ram and quill in conjunction with the vertical axis.

Benefits

- Active constantly and fully automatically

- Straightness of the ram axis from 0.02 mm up to 1,900 mm travel path

- Fully automatic alignment at right angles or parallel to the vertical axis

- 100% weight-independent precision with every milling head, quill, and facing head

Background

Especially large, heavy tools and changing between different milling heads of various weights often have an impact on the straightness of the machine ram.

Solution

The DBS dynamic ram balance compensation optimizes the machine accuracy fully automatically and immediately during machining. The tool is set at right angles or parallel to the machining axis with 100% precision at any time and without operator intervention.

The current position of the tools is monitored by a directly integrated measuring system on the machine ram and corrected by a dynamic angle adjustment of the machine ram. The machine ram is adjusted by an additional NC axis installed in the rear area of the machines vertical saddle slide. This enables both upward and downward compensation. DBS guarantees the constant straightness of the ram axis of 0.02 mm over the entire travel path of up to 1,900 mm – regardless of the various weights of the quills, milling heads, and tools.

Do you have any questions?

Get in touch with us.