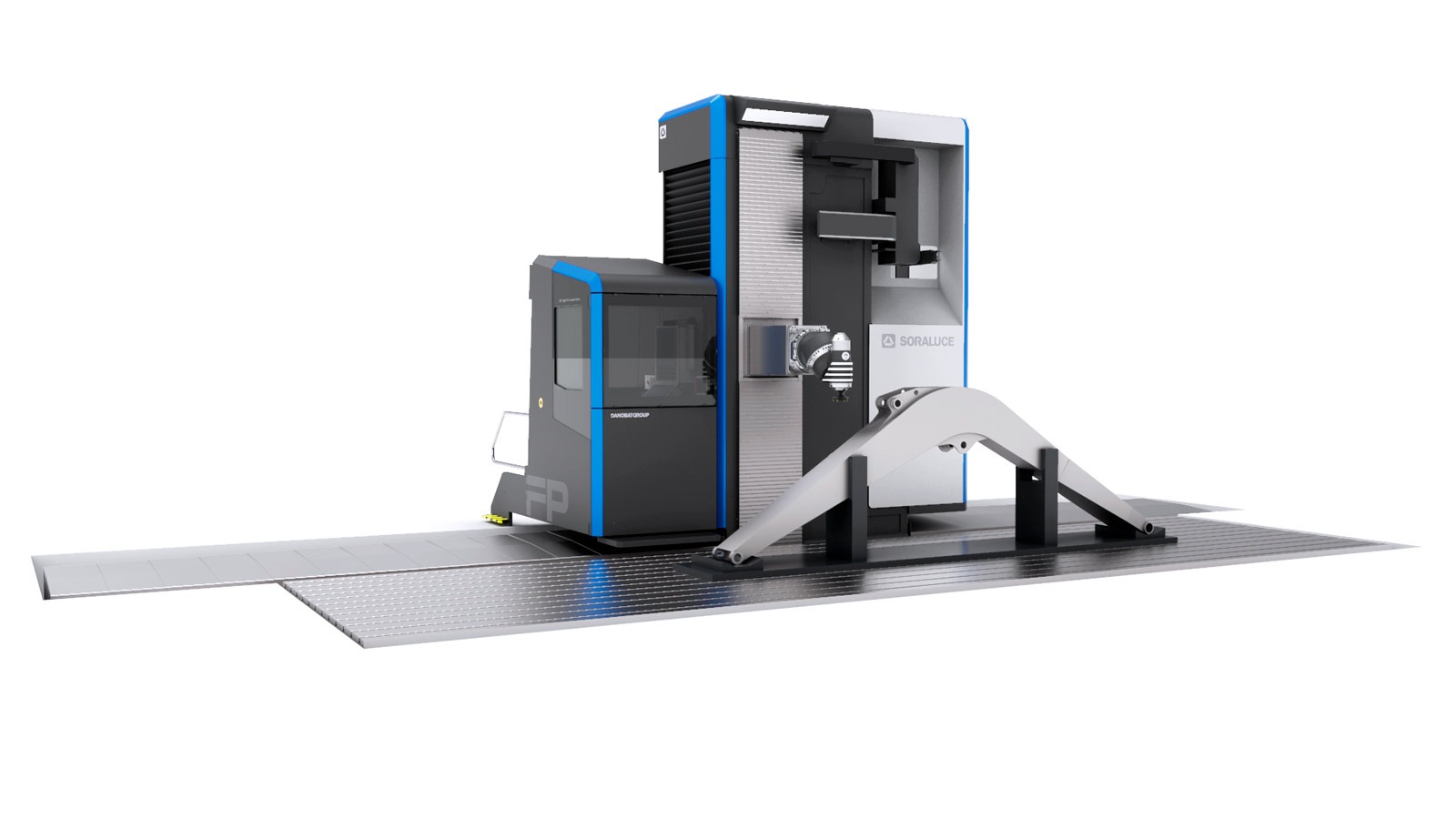

FLOOR TYPE MILLING-BORING MACHINE FP

floor type milling-boring machine FP

The SORALUCE FP is the ideal machine for a variety of applications when machining medium-sized components requiring maximum precision. Proven technology for use in industries such as the commercial vehicle industry, tool and mold making, and general mechanical engineering sectors.

Features

- Extremely low zero point of 767 mm

- Can be equipped with clamping tables of any size, NC rotary and travelling tables as well as clamping devices of any kind

- Multitasking: Milling and turning on one machine

- Universal milling head with main spindle clamping for turning – T-design

- Universal or orthogonal milling heads for machining at any desired angle

- Can be additionally equipped with a fixed quill 130 or 150 mm in diameter

- Fully automatic milling head changing system

- Integrated, water-cooled 43 kW optional 60 kW inline main spindle motor

- INA linear guiding systems with hydro mechanical damping slides

| Travel range X-axis (lengthwise) | 4,000 mm - unlimited |

| Travel range Y-axis (vertical) | 2,600 / 3,200 mm |

| Travel range Z-axis (crosswise) | 1,600 mm |

| Travel range W-axis / quill (option) | 700 / 800 mm (+ Z-axis 1,000 mm) |

| Milling head types | Universal milling head Orthogonal milling head Quill 130 or 150 mm in diameter Horizontal milling attachment Angle milling head |

| Automatic indexing milling head | stepless, simultaneous, 1° or 2.5° indexing |

| Milling head changing system | fully automatic by an adapter plate system with four zero-point clamps |

| Milling head changing system changing time | 60 seconds |

| Tool holder | ISO 50 / HSK 100 |

| Drive capacity | 43 or 60 kW at 100% ED |

| Torque | 900 / 2,000 Nm |

| Speed range | 6,000 / 7,000 rpm |

| Automatic tool changer | 40 / 60 / 80 / 100 / 120 magazine pockets |

| Travel speeds | 35,000 mm/min |

| Feed force | 20,000 N |

| CNC controller | Heidenhain TNC 640 Siemens Sinumerik One |

| Electronic hand wheel | with cable or radio wave |

| Coolant system | by spray ring and IKZ up to 70 bar |

| Coolant type | Coolant / air / air with MMS |