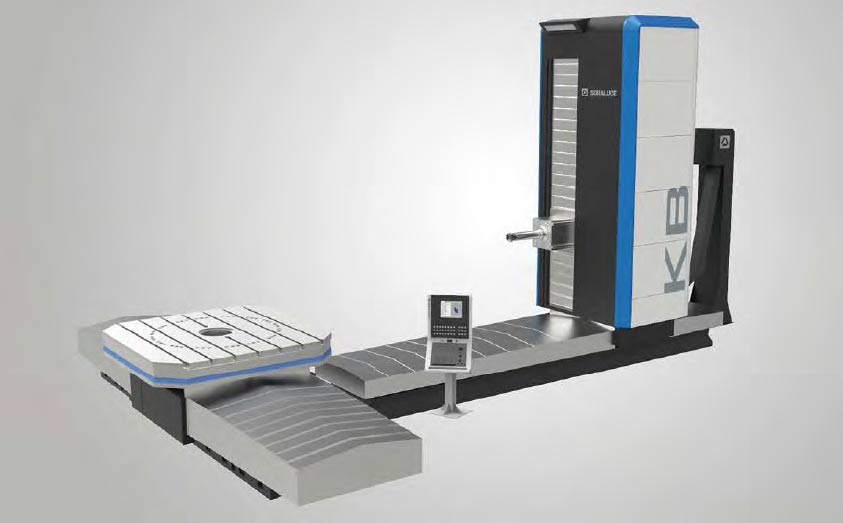

Horizontal boring machine KB-150-W

KB-150-W horizontal boring machine

The SORALUCE KB-150-W series is a modern table-type horizontal boring machine for efficient multi-face machining of large and precision workpieces with weights of up to 40,000 kg. The heavy cast iron design and INA linear roller guide systems guarantee maximum stability and precision. The automatic milling head changing system provides exceptionally high flexibility thanks to the automatically lowering milling heads for machining at any angle.

Features

- Column movable up to 5,000 mm and ram of 1,000 mm for large crosswise capacities

- 130-mm or 150-mm diameter quill plus automatically swiveling milling heads

- Speed range up to 3500 min-1 at 100% ED

- NC rotary table with indexing table from 2000 x 2000 to 2,500 x 2,500 mm

- Workpieces weighing up to 40,000 kg can be machined

- Fully automatic palletizing system to reduce set-up times

- Universal or orthogonal milling heads for machining at any angle

- Fully automatic milling head changing system

- Drive capacity: 54 kW at 100% ED

- INA linear guiding systems with hydro mechanical damping slides

| Travel range X-axis (lengthwise) | 3,000 / 4,000 / 5,000 mm |

| Travel range Y-axis (vertical) | 2,600 / 3,200 mm |

| Travel range Z-axis (crosswise) | 2,000 / 2,500 / 3,000 / 4,000 / 5,000 mm |

| Travel range W-axis / quill (option) | 700 / 800 mm |

| Milling slider traverse path | 1,000 mm |

| Rotary table size / maximum workpiece weight | 2,000 x 2,000 mm / 20,000 kg 2,000 x 2,500 mm / 20,000 kg 2,000 x 2,000 mm / 40,000 kg 2,000 x 2,500 mm / 40,000 kg 2,500 x 2,500 mm / 20,000 kg |

| Automation | with palletizing system |

| Quill | 130 / 150 mm in diameter |

| Milling head types | Universal milling head Orthogonal milling head NC facing head Ejector drill |

| Automatic indexing milling head | stepless, simultaneous, 1° or 2.5° indexing |

| Milling head changing system | fully automatic by an adapter plate system with four zero-point clamps |

| Changing time for quill / milling head changing system | 90 seconds |

| Tool holder | ISO 50 |

| Drive capacity | 54 kW at 100% ED |

| Torque | 2,344 / 4,490 Nm |

| Speed range | 3.500 rpm |

| Automatic tool changer | 40 / 60 / 80 / 100 / 120 / 150 magazine pockets or tool arena with a quantity according to customer requirements |

| Travel speeds | W-axis 15,000 / X-axis 20,000 / Y-axis 17,500 / Z-axis 35,000 mm/min |

| Feed force | 20,000 to 40,000 N |

| CNC control | Heidenhain TNC 640 Siemens Sinumerik One |

| Electronic hand wheel | with cable or radio wave |

| Coolant system | by spray ring and IKZ up to 70 bar |

| Coolant type | Coolant / air / air with MMS |