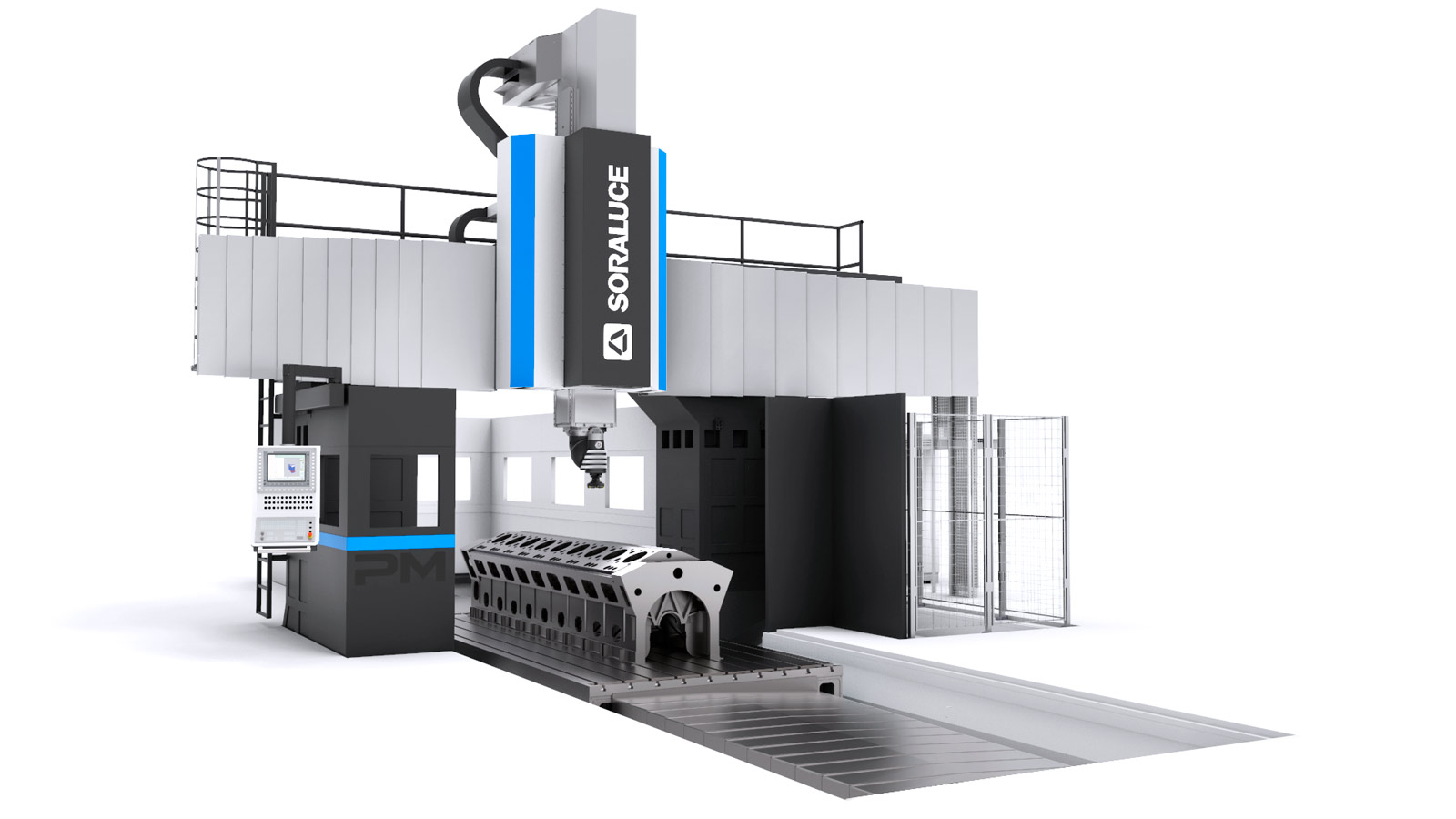

Portal milling machine PM

With fixed portal and movable machine table

Portal milling and boring centers of the PM series offer maximum precision and flexibility for machining the large parts of complex and high-precision workpieces. Outstandingly suitable for high-precision machining of prismatic and cubic workpieces in the mechanical engineering and tool and mold making sectors. An extremely heavy cast iron design with optimum damping properties and the INA linear guiding system equipped with hydro mechanical damping slides as the basis for the ultra-modern PM portal milling and boring centers.

Optionally available in gantry design.

Features

- Extremely heavy cast metal design machine concept

- Highly dynamic with travel speeds of up to 35,000 mm/min

- Large machine table with triple or quadruple guides

- Universal or orthogonal milling heads for machining at any desired angle

- Heavy vertical milling heads and special milling heads for every application

- Fully automatic milling head changing system

- Spindle power from 43 kW to 60 kW

- INA linear guiding systems with hydro mechanical damping slides

- DAS+ vibration damping for increased productivity

- Complete splash/chip guards including chip management system

- User-friendly machine design

| Table lengths | 5,000 / 6,000 / 7,000 mm |

| Table widths | 2,500 / 3,000 mm |

| Travel range X-axis (lengthwise) | 4,600 mm - unlimited |

| Travel range Y-axis (crosswise) | 4,000 / 4,500 mm |

| Travel range Z-axis (vertical) | 1,500 / 2,000 mm |

| Distance between machine columns | 3,520 / 4,020 mm |

| Clearance under cross beam | 2,100 / 2,600 mm |

| Spindle power: | 43 / 60 kW at 100% ED |

| Spindle speed range | 6,000 / 7,000 rpm |

| Tool holder | ISO-50 / HSK-100 |

| Automatic tool changer | 40 / 60 / 80 / 100 / 120 / 140 magazine pockets |

| Travel speeds | (X) 30,000 / (Y + Z) 35,000 mm/min⁻¹ |

| CNC controller | Heidenhain TNC 640 Siemens Sinumerik One |

| Coolant lubricant system | by spray rose ring and IKZ up to 70 bar |